✅ Eco-friendly Yarns – Made from recycled PET or bio-based polymers to reduce petroleum dependence and carbon footprint.

| Material/Brand | Material Source | Sustainability Highlights |

| Bio Polyester Sorona® |

Fermented corn → Glucose → PDO + PTA → Polymerization → Yarn | Up to 30% CO₂ and 63% GHG reduction vs. Nylon; USDA, OEKO-TEX® Standard 100 Class I |

| Bio Nylon BASF® | CPL + Biomethane + Castor Oil→ Yarn | Reduces fossil dependence and carbon emissions; Certified under RCS, ISCC PLUS, REDcert² |

| Recycled Polyester UNIFI® | 100% bottles → Washed, sorted, flaked, polymerized with EG → Chips → Yarn | Fully post-consumer; Verified by U Trust®, FiberPrint®, GRS, SCS Recycled Content |

| Recycled Nylon Seawastex® | Melted and purified post-industrial nylon waste (e.g., fishing nets) → Caprolactam → Yarn | Traceable batch system (Transaction Certificate); GRS certified |

✅ Sustainable Membranes – Options include recycled PU, eco (r) poly membranes (TPEE), recycled TPU, and Porlite microporous membranes (solvent-free & PFAS-free), all designed for breathable and durable water protection.

| Eco Poly Memebrane | PET | RECYCLE PU | TPU | |

| WP/ MVP | 20K/20K | 10K/10K | 30K/30K | 15K/15K |

|

Solvent |

None | None | DMF | None |

|

Elasticity |

300% | X | 200% | 220% |

| Recyclable | Yes | Yes | X | X |

| Material Source | Production Waste | Production Waste | Production Waste | X |

| Melting Point | 180℃ | 170℃ | 170℃ | 150℃ |

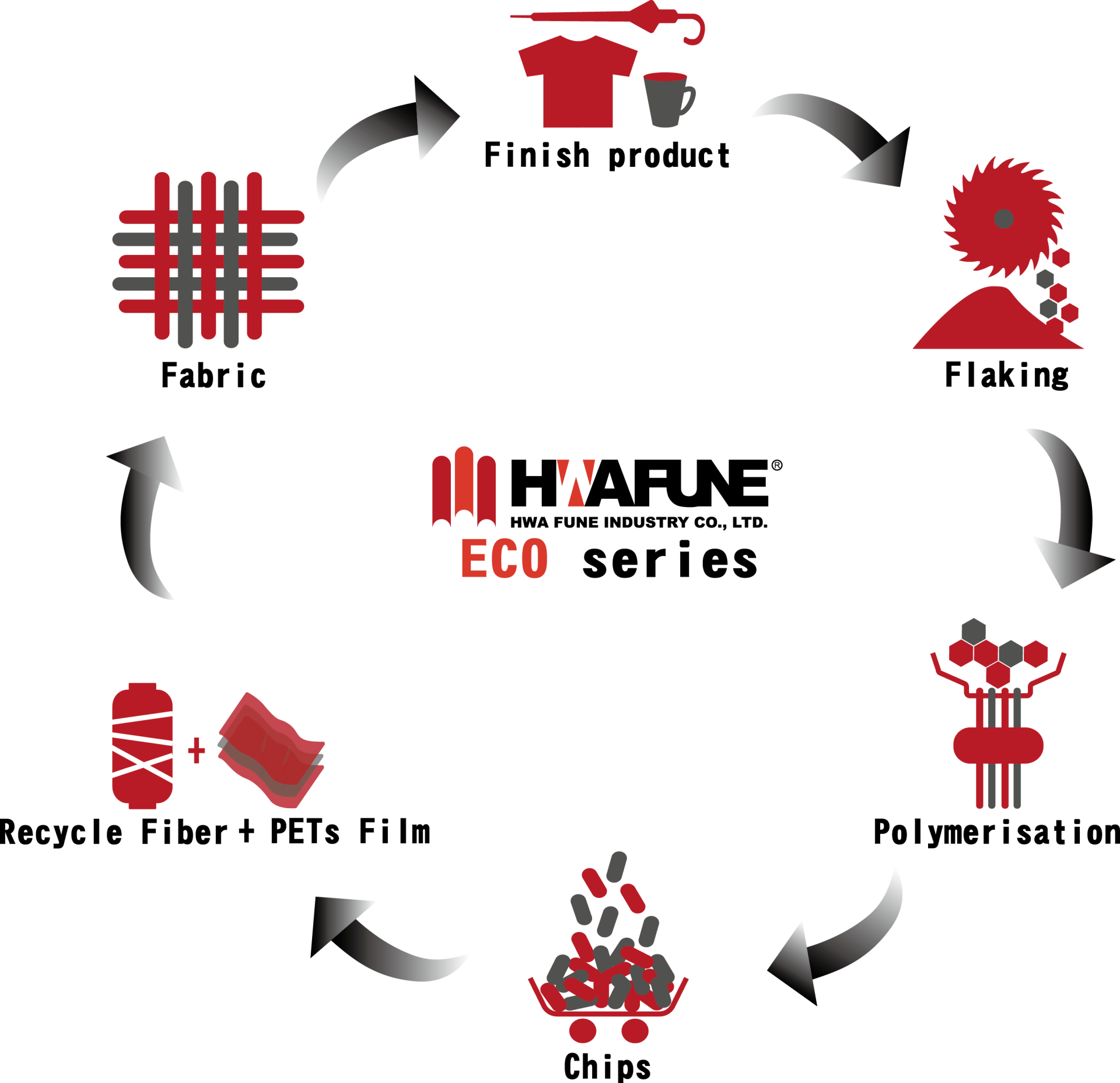

For sustainable resource development, we go beyond offering single-material solutions and are committed to advancing ECO r-POLY.

This material is produced by chemically depolymerizing recycled polyester (rPET) into its monomers, which are then re-polymerized into ECO r-POLY.

The chemical recycling process generates significantly lower carbon emissions compared to using petroleum-based raw materials, while the final product maintains the same physical properties as ECO POLY.

|

|

|

60% less energy required

50% less water required

Looking For Trusted Eco Fabric Manufacturers? 👉 Contact Us Now

✅ Eco-friendly Yarns – Made from recycled PET or bio-based polymers to reduce petroleum dependence and carbon footprint.

| Material/Brand | Material Source | Sustainability Highlights |

| Bio Polyester Sorona® |

Fermented corn → Glucose → PDO + PTA → Polymerization → Yarn | Up to 30% CO₂ and 63% GHG reduction vs. Nylon; USDA, OEKO-TEX® Standard 100 Class I |

| Bio Nylon BASF® | CPL + Biomethane + Castor Oil→ Yarn | Reduces fossil dependence and carbon emissions; Certified under RCS, ISCC PLUS, REDcert² |

| Recycled Polyester UNIFI® | 100% bottles → Washed, sorted, flaked, polymerized with EG → Chips → Yarn | Fully post-consumer; Verified by U Trust®, FiberPrint®, GRS, SCS Recycled Content |

| Recycled Nylon Seawastex® | Melted and purified post-industrial nylon waste (e.g., fishing nets) → Caprolactam → Yarn | Traceable batch system (Transaction Certificate); GRS certified |

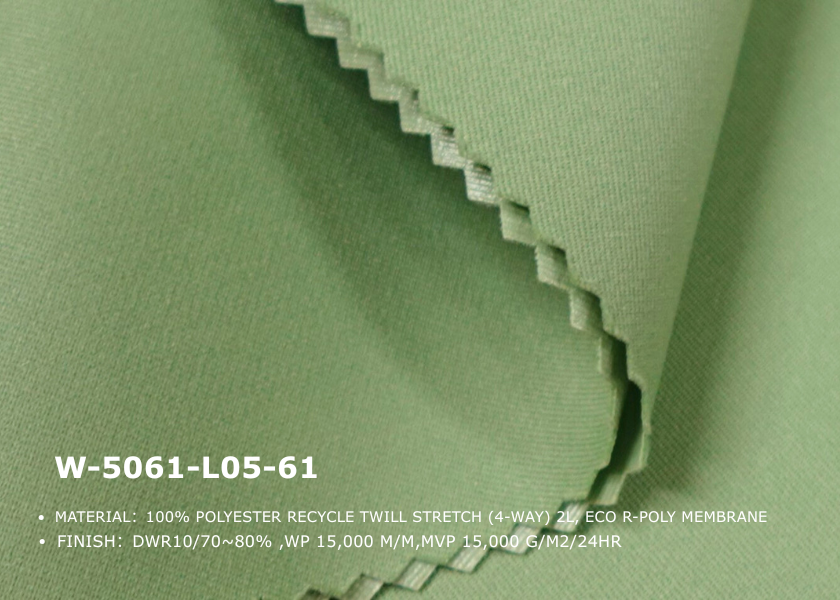

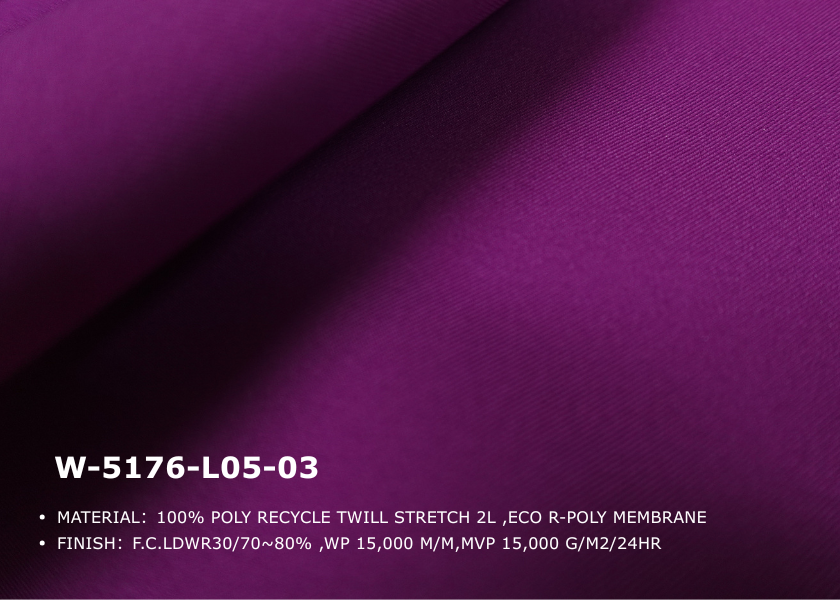

✅ Sustainable Membranes – Options include recycled PU, eco (r) poly membranes (TPEE), recycled TPU, and Porlite microporous membranes (solvent-free & PFAS-free), all designed for breathable and durable water protection.

| Eco Poly Memebrane | PET | RECYCLE PU | TPU | |

| WP/ MVP | 15K/15K | 10K/10K | 30K/30K | 15K/15K |

|

Solvent |

None | None | DMF | None |

|

Elasticity |

300% | X | 200% | 220% |

| Recyclable | Yes | Yes | X | X |

| Material Source | Production Waste | Production Waste | Production Waste | X |

| Melting Point | 180℃ | 170℃ | 170℃ | 150℃ |

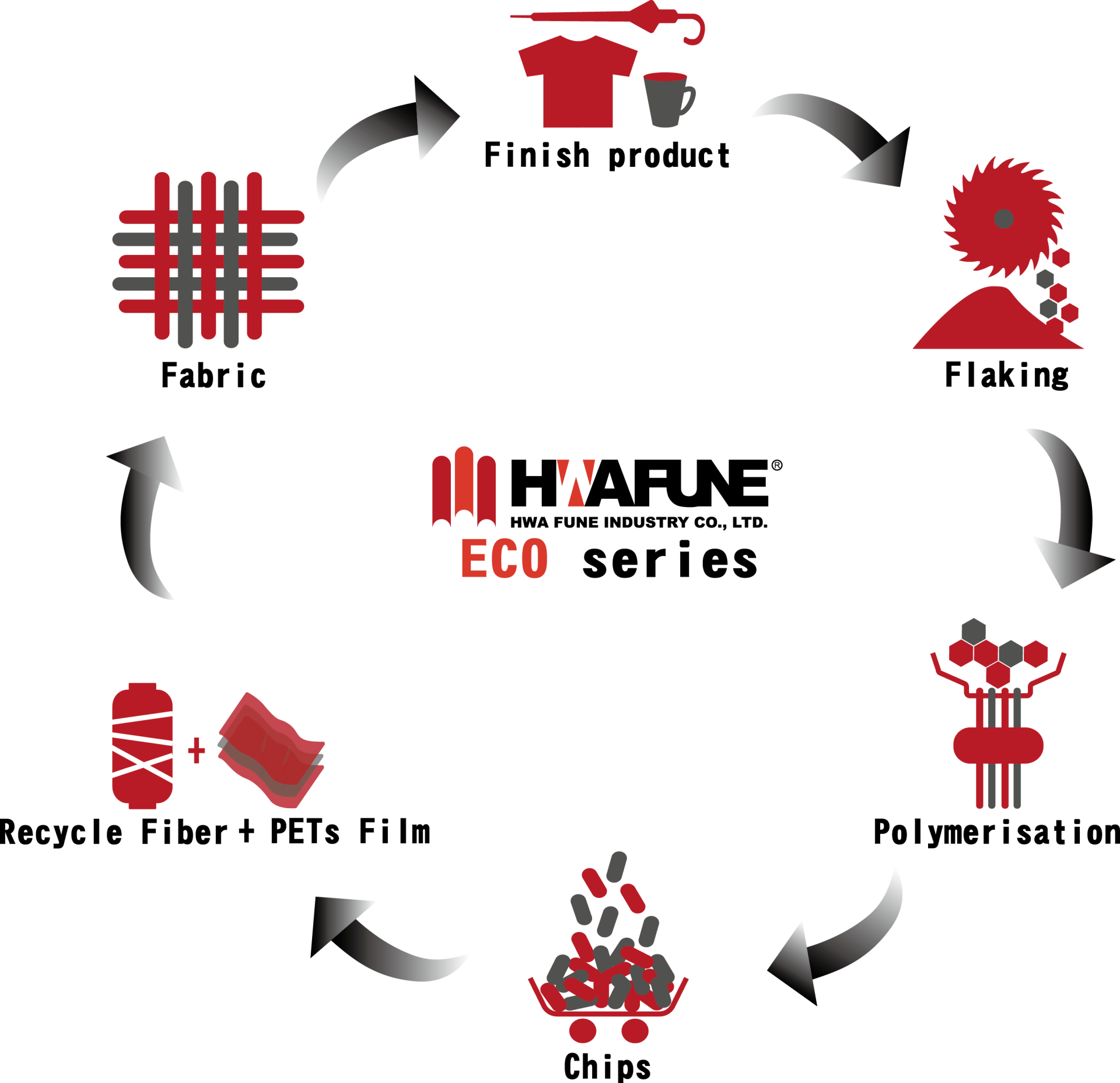

For sustainable resource development, we go beyond offering single-material solutions and are committed to advancing ECO r-POLY.

This material is produced by chemically depolymerizing recycled polyester (rPET) into its monomers, which are then re-polymerized into ECO r-POLY.

The chemical recycling process generates significantly lower carbon emissions compared to using petroleum-based raw materials, while the final product maintains the same physical properties as ECO POLY.

|

|

|

60% less energy required

50% less water required

Looking For Trusted Eco Fabric Manufacturers? 👉 Contact Us Now