Mountaineering Fabric Solutions

Mountain sports—such as rock climbing, snow mountain trekking, and technical mountaineering—place high structural demands on outerwear due to equipment weight, contact friction, and sudden weather changes.

To meet these challenges, we develop tear-resistant, abrasion-resistant, and weatherproof fabric solutions that maintain performance in harsh alpine environments.

These recommended fabric features align with the priorities of leading outdoor gear brands and activewear users.

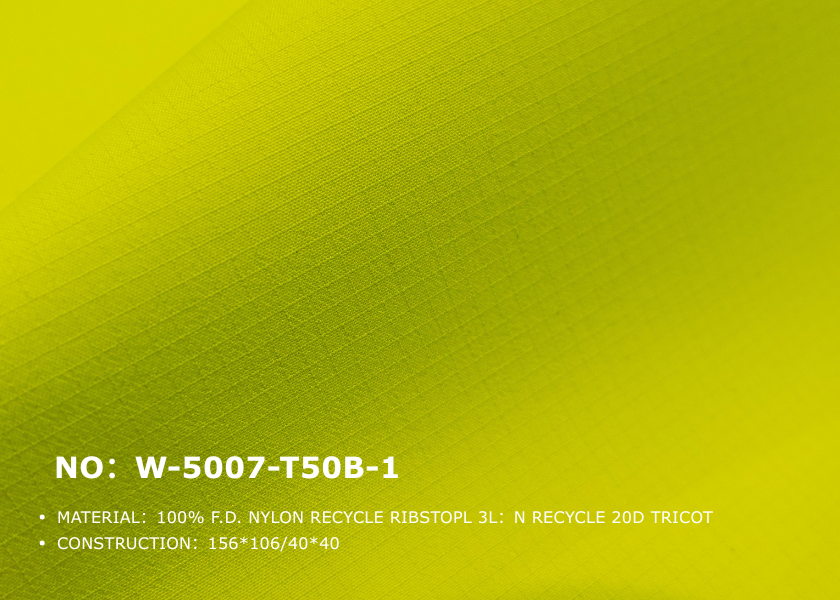

Nylon Yarn Base

‣ Engineered with durable nylon yarns to resist tearing and mechanical stress, this tear-resistant outdoor fabric helps extend the lifespan of technical jackets and hiking gear.

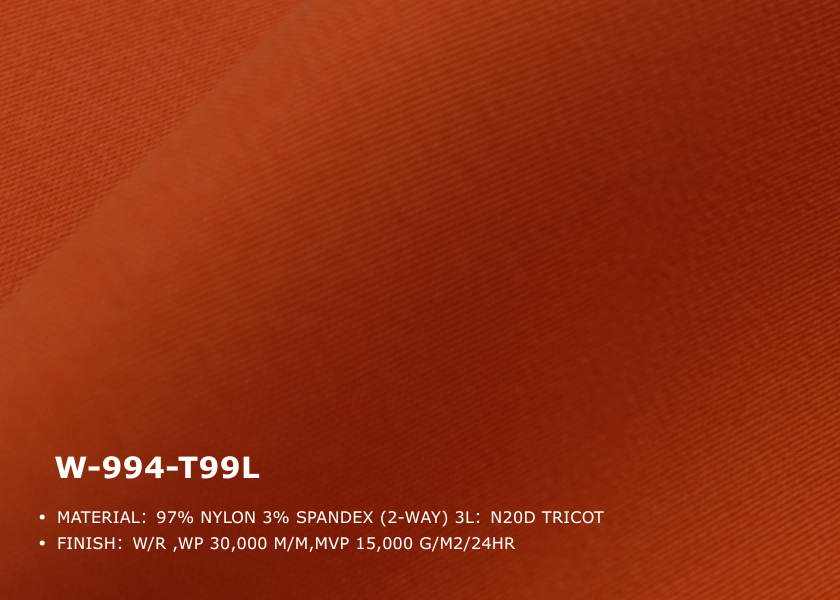

Stretch or Spandex

‣ Built-in mechanical or spandex stretch improves movement range, making it ideal for stretch sportswear fabrics used in mountaineering pants and climbing shells.

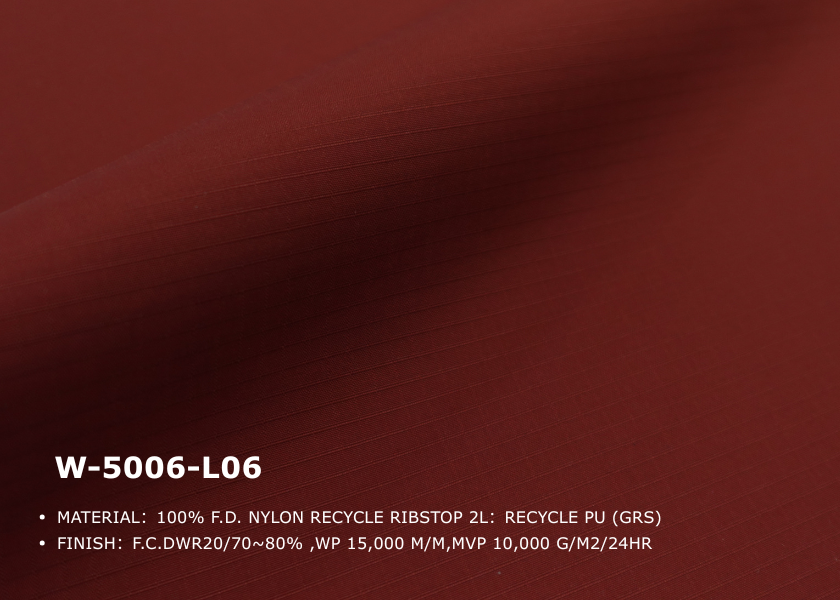

Low-Denier Yarns

‣ Low-denier yarns reduce overall fabric weight, making it perfect for lightweight waterproof fabric applications such as trekking jackets or breathable outer layers.

Durable Water Repellent (DWR)

‣ Applied to surface fabrics to repel light rain and splashes, this DWR jacket fabric helps maintain dryness and comfort in unpredictable outdoor environments.

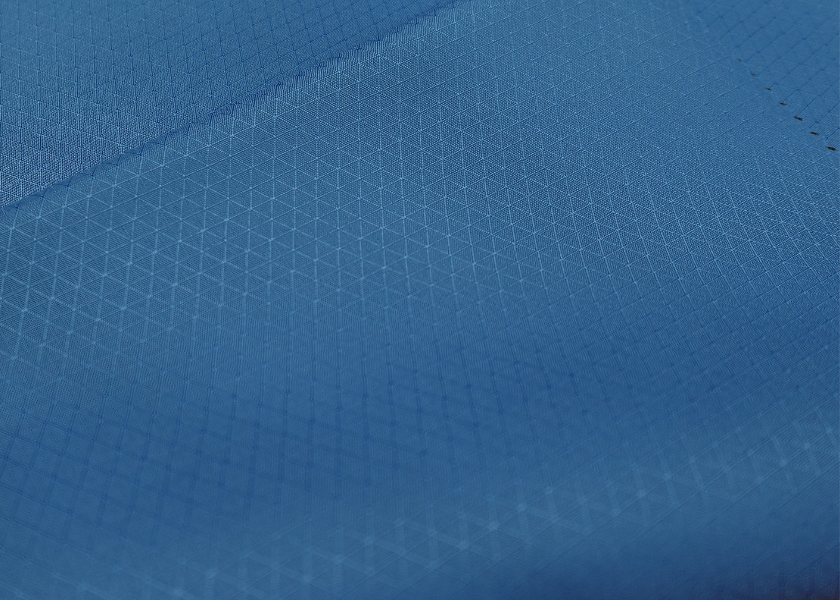

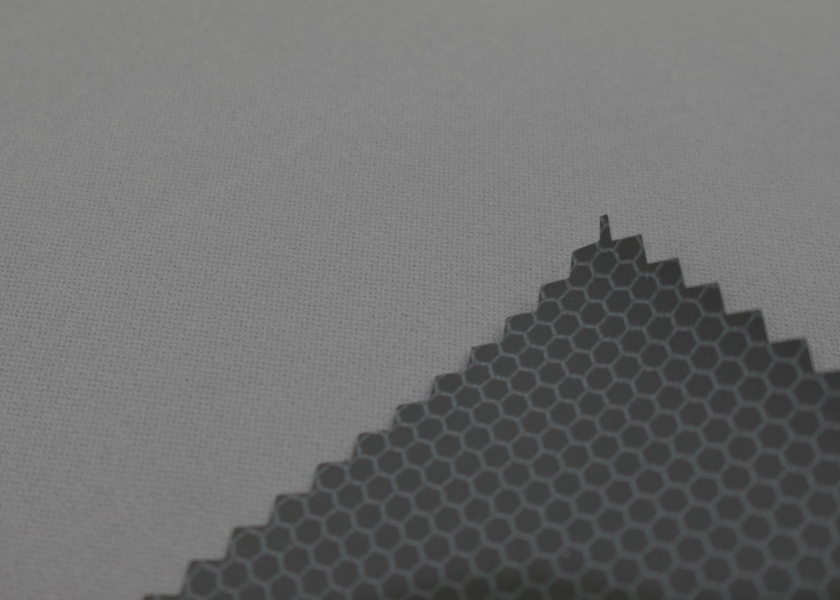

Textured Pattern

‣ Constructions like ripstop fabric or dobby add surface texture to reduce gear abrasion, commonly found in abrasion-resistant outdoor textiles for climbing jackets and backpacks.

What Happens When A Small Snag Turns Into A Large Tear?

That’s where tear strength matters.

Tear strength is a key indicator of fabric integrity—especially in applications where safety and durability are critical, such as rock climbing gear, workwear, or outdoor jackets.

In real use, small snags or scuffs can quickly turn into larger tears if the fabric lacks sufficient structural resilience. For example, a cuff caught on a branch or a scuffed hemline may seem minor at first, but with movement and stress, the damage can expand significantly.

Tearing often starts when friction or force weakens individual yarns. Once one breaks, adjacent yarns begin to fail in sequence, eventually compromising the entire fabric.

That's why we rigorously test tear strength to ensure our fabrics maintain structural performance in real-world, high-stress conditions.

Learn more🔗 «Fabric Tearing Strength: Testing, Factors, and Solutions | HWAFUNE TEXTILE»

Looking For Trusted Mountaineering Fabric Manufacturers? 👉 Contact Us Now

Mountaineering Fabric Solutions

Mountain sports—such as rock climbing, snow mountain trekking, and technical mountaineering—place high structural demands on outerwear due to equipment weight, contact friction, and sudden weather changes.

To meet these challenges, we develop tear-resistant, abrasion-resistant, and weatherproof fabric solutions that maintain performance in harsh alpine environments.

These recommended fabric features align with the priorities of leading outdoor gear brands and activewear users.

Nylon Yarn Base

‣ Engineered with durable nylon yarns to resist tearing and mechanical stress, this tear-resistant outdoor fabric helps extend the lifespan of technical jackets and hiking gear.

Stretch or Spandex

‣ Built-in mechanical or spandex stretch improves movement range, making it ideal for stretch sportswear fabrics used in mountaineering pants and climbing shells.

Low-Denier Yarns

‣ Low-denier yarns reduce overall fabric weight, making it perfect for lightweight waterproof fabric applications such as trekking jackets or breathable outer layers.

Durable Water Repellent (DWR)

‣ Applied to surface fabrics to repel light rain and splashes, this DWR jacket fabric helps maintain dryness and comfort in unpredictable outdoor environments.

Textured Pattern

‣ Constructions like ripstop fabric or dobby add surface texture to reduce gear abrasion, commonly found in abrasion-resistant outdoor textiles for climbing jackets and backpacks.

What Happens When A Small Snag Turns Into A Large Tear?

That’s where tear strength matters.

Tear strength is a key indicator of fabric integrity—especially in applications where safety and durability are critical, such as rock climbing gear, workwear, or outdoor jackets.

In real use, small snags or scuffs can quickly turn into larger tears if the fabric lacks sufficient structural resilience. For example, a cuff caught on a branch or a scuffed hemline may seem minor at first, but with movement and stress, the damage can expand significantly.

Tearing often starts when friction or force weakens individual yarns. Once one breaks, adjacent yarns begin to fail in sequence, eventually compromising the entire fabric.

That’s why we rigorously test tear strength to ensure our fabrics maintain structural performance in real-world, high-stress conditions.

Learn more🔗 «Fabric Tearing Strength: Testing, Factors, and Solutions | HWAFUNE TEXTILE»

Looking For Trusted Mountaineering Fabric Manufacturers? 👉 Contact Us Now