The Global Recycling Gap and Why Mono-material Fabrics Matter

The global apparel industry is under mounting pressure from sustainability goals and circular economy policies. According to the Ellen MacArthur Foundation, less than 1% of textiles are recycled back into new clothing, while another 12% are downcycled into lower-value products; the vast majority is lost to landfill or incineration. One of the key barriers lies in the recycling of multi-fiber blended fabrics: once a fabric combines cotton, polyester, and more than 5% spandex, the tightly interwoven fibers make it impossible to process through current mechanical recycling systems.

In contrast, mono-material textiles—garments made entirely from a single fiber such as 100% polyester or 100% nylon—can directly enter same-polymer recycling processes without disassembly.

Regulatory Drivers: DPP / ESPR / WRAP

The EU Ecodesign for Sustainable Products Regulation (ESPR) entered into force in July 2024, establishing a framework that will soon require brands to disclose product durability, composition, and recyclability. A cornerstone of this framework is the Digital Product Passport (DPP), which mandates transparency across the supply chain.

Waste and Resources Action Programme (WRAP) emphasizes that improving textile recyclability requires following the Resource Hierarchy and Design for Circularity principles: prioritize mono-material design and eliminate unnecessary components to simplify recycling.

For functional fabric suppliers, simpler, single-material compositions significantly reduce the cost of data collection and verification. In practice, mono-material textiles make it easier for brands to demonstrate compliance with ESPR, DPP, and related frameworks such as Corporate Sustainability Reporting Directive (CSRD) and Extended Producer Responsibility (EPR), lowering due diligence risks while providing a clear recycling pathway.

Technical Boundaries and Market Reality

While polyester mono-material fabrics excel in recycling efficiency, they are not a universal solution. Removing blends often means sacrificing elasticity, moisture management, or breathability, limiting their use in high-performance sportswear or professional outdoor gear.

Infrastructure remains a major challenge: even when garments are designed for recyclability, most regions lack operational textile-to-textile recycling systems. Mono-material design, therefore, must be paired with investment in recycling capacity, policy enforcement, and industry collaboration to deliver its full potential.

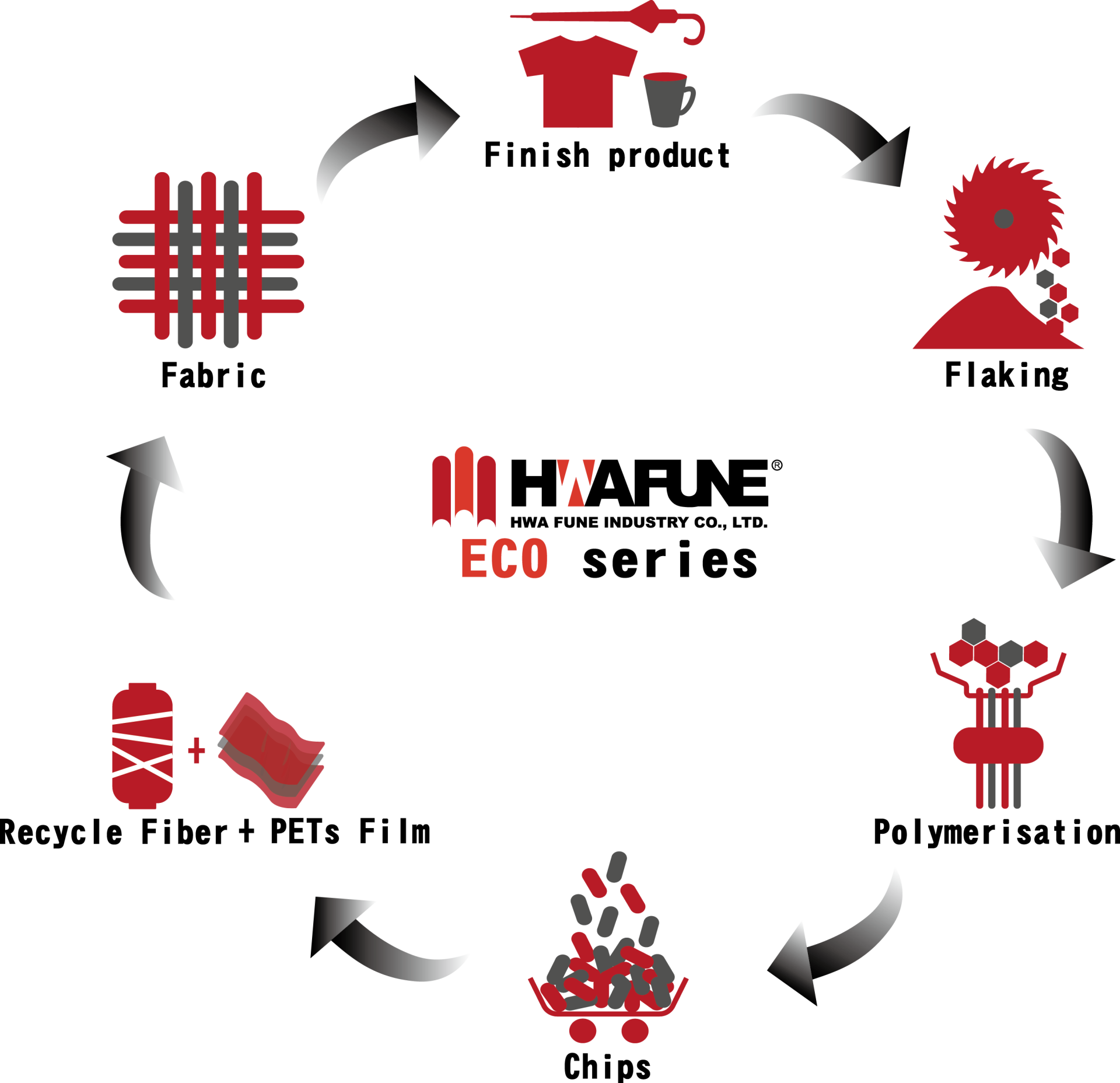

Hwafune's Approach: Balancing Mono-material Innovation

As an outdoor performance fabric supplier, Hwafune has been actively developing singlematerial fabrics to meet both performance and recyclability demands:

- In its PET / Eco-Poly system with polyester face fabrics, Hwafune has achieved stable 30K/30K hydrostatic pressure and moisture vapor permeability, with a silk-like smooth hand feel. By engineering mechanical stretch, the fabrics retain elasticity without added spandex, enabling same-polymer recycling.

- Traditional mono-material double-weave fabrics often weigh 200–300 gsm, too heavy for outdoor markets. Hwafune addressed this by introducing SORONA®-based fabrics, verified with carbon accounting, 100-200 gsm, delivering both lightness and recyclability.

- Pricing perspective: Compared to fabrics of similar high quality, Hwafune’s monomaterial textiles offer a distinctly higher cost–performance value, thanks to the stability already achieved in their technology.

- Nylon mono-material fabrics remain under active development. Current prototypes face limitations in both cost and performance.

- Polypropylene (PP) mono-material fabrics, when integrated with Hwafune’s PORLITE® PP membrane, present notable sustainability potential; however, they remain at the development stage and face substantial technical and economic hurdles.

These developments illustrate that mono-material fabric innovation is not just about recyclability—it is about balancing performance, sustainability, and cost in the supply chain.